CMMS Software – Definition, Features and Benefits

- CMMS Software (Computerized Maintenance Management Software) is a comprehensive tool that automatically plans, schedules and tracks maintenance for all of your equipment and facilities.

- Centralize maintenance records, reduce downtime, improve production and profitability.

CMMS Software Trusted by Thousands Worldwide

What is CMMS Software?

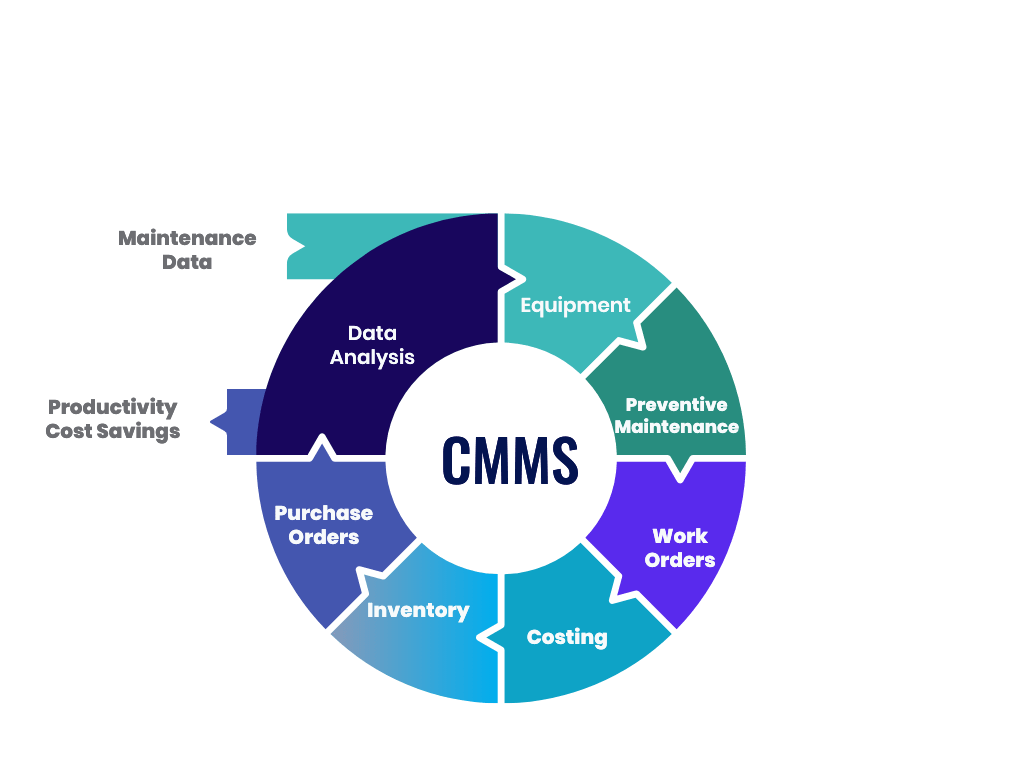

A Computerized Maintenance Management System (CMMS) is a powerful software solution designed to effectively manage maintenance departments. CMMS Software efficiently tracks and organizes all maintenance processes while automating preventive maintenance tasks.

CMMS helps manage all aspects of your maintenance operation. Functions include equipment management, preventive maintenance, streamlining work orders, cost tracking, inventory management, purchasing, reporting and data analysis. Results include extended equipment lifespans and reduction in maintenance costs.

How Does CMMS Work?

Centralized Paperless Record keeping

Centralize and share your maintenance data with safe, secure and reliable CMMS Software.

Mobile Maintenance Management

Perform and track maintenance on the go and in real time. Easily find the information you need to get the job done.

Full Maintenance Automation

From generating preventive maintenance work orders to automatic inventory re-ordering, CMMS returns time to you.

Manage Resources and Labor

Maximize efficiency by balancing workloads. Know what parts you have on hand and locate them with ease.

Intelligent Data Analysis

Make confident business decisions with customizable data exports and reporting. CMMS dashboard shows a snapshot of status.

Streamline Work Order Management

Plan and priototize work orders. Automate Work Order Requests. View status and track Downtime.

What Industries Use CMMS Software?

What are the Features of CMMS Software?

CMMS Software will Enhance your efficiency, productivity, and overall maintenance performance. Take control of your maintenance tasks and unlock the potential of your operations today.

Intelligent Budget Management

Reporting and Data Analysis

CMMS Plans to Suit your Needs and your Budget

What does CMMS Software do?

Why does my company need CMMS Software?

What does Research on CMMS Show?

COGZ CMMS fully automates your maintenance department. Less time spent scheduling maintenance results in more time returned to you and your team. From automatically generating preventive maintenance to automated notifications, maintenance management software helps you get more work done in less time.

By keeping a comprehensive record of maintenance activities, CMMS empowers management to make informed decisions that enhance overall efficiency. The benefits of implementing CMMS Software include extended equipment lifespan, reduced breakdowns and downtime, and lower maintenance costs. Discover the power of COGZ and revolutionize your maintenance management today.

- The Journal of Quality in Maintenance Engineering states that CMMS Software facilitates a deliberate approach to managing an organization’s assets (Ashraf W. Labib, Mechanical, Aerospace and Manufacturing Engineering, University of Manchester Institute of Science and Technology (UMIST), Manchester, UK, 2004).

- Software Connect reports that 66% of facilities use a CMMS to manage their maintenance department.

What are the Benefits of CMMS Software?

Maximize Uptime

Preventive Maintenance stops breakdowns before they happen. This improves equipment reliability, maximizes uptime and improves asset lifespans.

Automate Preventive Maintenance Tasks

CMMS Software automatically schedules your preventive maintenance tasks saving you the time and hassle of doing it yourself. Switching focus from corrective to preventive maintenance keeps your equipment up and running smoothly. Frequent breakdowns become a thing of the past. With fewer breakdowns more time is available to manage your maintenance department.

Streamline Workflows

COGZ organizes and streamlines Work Orders and Workflows. Create, assign and complete Work Orders and Work Order Requests. Balance Workflows for each employee and improve productivity. Print Work Orders or send them directly to assigned technicians via email.

Equipment/ Asset Management

Store and track important information on all of your Equipment and Assets. CMMS Software collects and records data on your assets as you perform maintenance, including schedules, meter readings, locations, and downtime. Easily track costs and store documents such as diagrams and manuals.

Manage Spare Parts Inventory

Computerized Maintenance Management Software manages your spare parts inventory. Keep an accurate count of inventory on hand as well as what inventory is being used on work orders. Use this information to determine which parts are most commonly used and should be kept in stock. Beat supply chain disruptions by automatically reordering inventory when stock falls below a specified level. Have all of the information about your inventory including cross references and alternative vendors available so that you can get the parts you need when you need them.

Reduce inventory carrying costs by having the right amount of inventory in stock. Eliminate the need for expensive overnight freight by re-ordering parts before you run out. Knowledge is power and you will have access to all of the data available on all of your spare parts.

Work Order Requests

Allow employees outside of the maintenance department to request work orders. Get better information about the job that needs to be done from the person who needs the work completed. Save maintenance department time by allowing others to directly request work. Status alerts update the requester automatically so that there is no need for them to contact you.

Work Order Reminders

Never forget a work order with Work Order Reminders. Preventive maintenance and corrective work orders will never slip through the cracks again. CMMS never forgets your important work orders. Visual reminders will notify you if tasks become overdue. Increase equipment reliability by reliably completing all of your work orders.

Streamline Purchasing

Automatically create purchase orders with the inventory information already in your CMMS. Email purchase orders to your vendors or to other employees for approval.

Leverage Data for Better Decision Making

CMMS Software keeps track of all the maintenance activities that are being performed. The data collected can be used to make better decisions. Reports are available to summarize data on a variety of topics. Use reports to keep management informed about status or to analyze data. Having all of the information available shows you what equipment is costing you the most money and why. Use the information gathered to make informed decisions.

What Does CMMS Software Do?

Our CMMS Software has all the features your maintenance team needs, and many more.

Preventive Maintenance Work Orders

Preventive Maintenance is the heart and soul of the COGZ CMMS System. Our mobile platform makes scheduling your preventive maintenance a breeze. Watch your equipment breakdowns become the exception instead of the normal. Think of what you can do without the stress of putting out fires.

Breakdown Work Orders

When breakdowns do occur, COGZ CMMS quickly provides you with the information you need to get things up and running. Documentation of the problem can even be done after the equipment is back in service. These details can then be reviewed as part of your predictive maintenance plan. COGZ streamlines work order management.

Equipment Master Console

Having all the information your team requires in one place makes everyone’s job easier. CMMS Software tracks everything from work order history to warranty expiration dates to spare parts locations to manuals and drawings. Everything you need is right there on the Equipment Master Console. Looking for maintenance costs for last year? Want to know which part is replaced most often? It’s all a single click away.

Simple Inventory Control

Whether for Preventive or Unscheduled maintenance, you need the parts to be available so you can promptly complete the job. The inventory management system provides all the information you need to maintain a proper spare parts inventory. This feature alone will help your department contribute to your company’s bottom line.

Data Security

COGZ CMMS understands the importance of data security. That’s why we offer COGZWeb Cloud hosting or an on-premises version to cater to the unique needs of every customer. Rest assured, we prioritize the utmost security to protect your valuable information.

Reduce Downtime

Keep your equipment running reliably, reducing breakdowns to the lowest possible level. Discover the power of proactive maintenance and streamline your operations with our user-friendly and customizable CMMS solution. With COGZ, you can reduce stress, increase efficiency, and achieve significant cost savings.

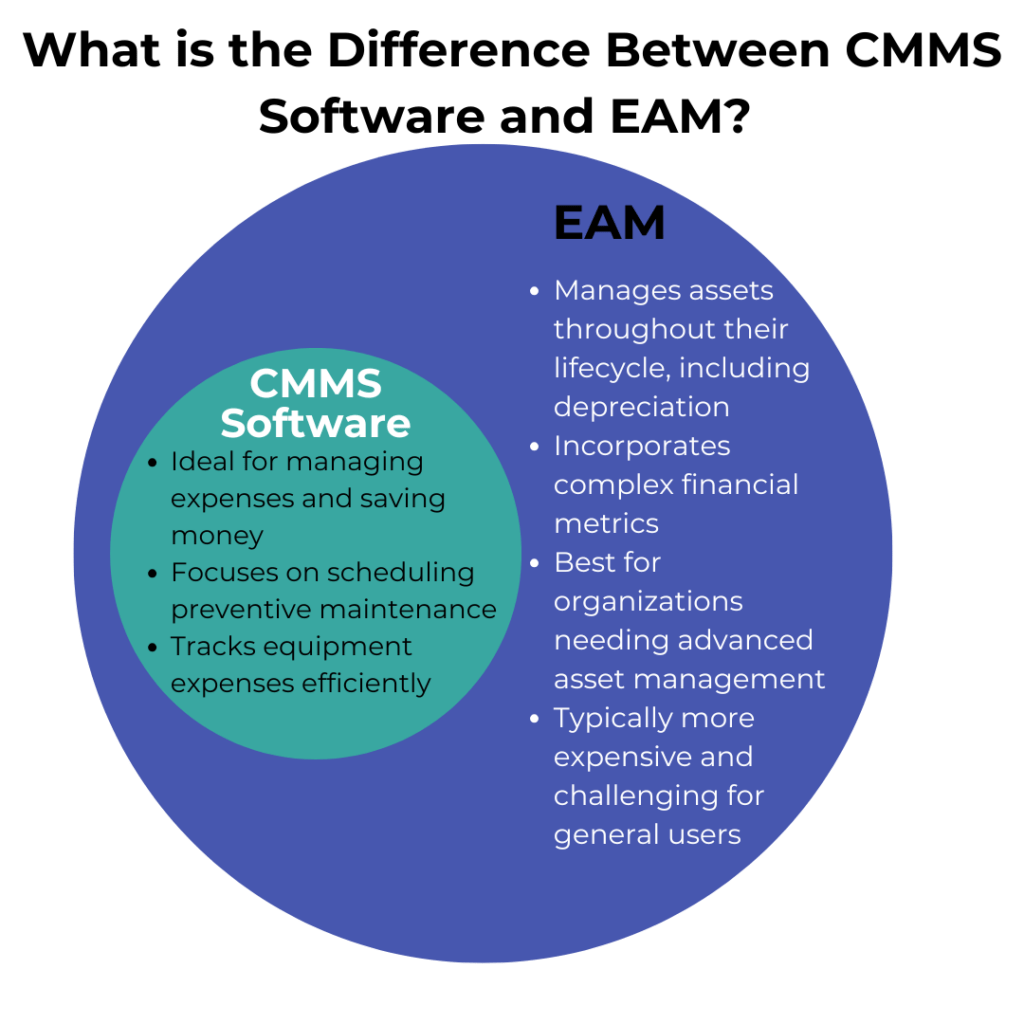

What is the Difference Between CMMS Software and EAM?

Both systems have the goal of maximizing asset life and productivity along with cutting costs. Which type of software is the right choice for my maintenance operation? The answer is that it depends. If the primary goal is to manage costs and save money then a CMMS System is the best choice. A CMMS System can easily accomplish this by scheduling preventive maintenance and tracking expenses for equipment. Enterprise Asset Management Systems manage assets throughout their lifecycles including depreciation and heavy financial metrics. They are however, more costly as well as more challenging for the average maintenance user. Learn more at our blog post CMMS vs EAM

How can CMMS Software Cut Maintenance Costs?

Decrease Equipment Downtime

CMMS Software helps you to stick to a preventive maintenance schedule. Performing proactive maintenance keeps your equipment running smoothly, avoiding downtime. Expenses related to downtime often spiral out of control due to a snowball effect.

Extend Equipment Lifespans

Timely preventive maintenance reduces unnecessary wear and tear on your equipment. Parts are less likely to wear out and break. Potential problems with equipment may be caught before they occur, which can prevent catostrophic failure. Well maintained equipment will continue to operate for a much longer period of time, postponing replacement costs.

Improve Maintenance Team Productivity

CMMS Software has many tools that improve productivity and allow maintenance technicians to get more work done in less time. Reduced paperwork, Work Order Requests, Email, and mobile access are just a few of the tools that improve productivity. More work orders completed in less time results in substantial cost savings.

Energy Efficiency

Equipment that is in peak condition optimizes its energy consumption. CMMS Software will help you ensure that all of your equipment is in the best possible condition maximizing your energy savings potential.

Eliminate Duplicate Work

COGZ CMMS Software provides a centralized platform for all of your maintenance data. Paperwork and duplication of work can be reduced to zero when used properly.

Data Driven Decisions

CMMS software collects data as maintenance activities are performed. This data should be analyzed and used to make better maintenance management decisions. Examples include, deciding to sell equipment that is costing too much money to maintain and hiring another maintenance technician due to high maintenance backlog. Both items will cost money, but will produce savings in excess of costs.

How to Evaluate CMMS Software

Selecting the right CMMS can be the difference between success and failure. You need CMMS that meets your objectives and is easy enough for your staff to use. Find a CMMS that is powerful enough to be used in multi-site facilities and multi-industries. Below are some tips for selecting the right CMMS Software

- Know your maintenance goals

- Determine what features you need

- Prioritize software with quick implementation

- Choose your KPIs

- Review standard reports

- Set a budget

CMMS Software Benefits

Software Connect reports that 66% of facilities use a CMMS to manage their maintenance department. COGZ automates your maintenance department so you can spend your time on more important work. It tracks all of your maintenance activities so you know what has been done and what still needs to be done. It stores all your maintenance data do you can access it when you need it. Benefits include:

- Easy to use interface for fast implementation

- Increase Uptime – Reduce Breakdowns and Downtime

- Increase wrench time

- Huge Cost Savings

- Make Better decisions with data collected

- Have the parts you need when you need them

- Streamline the Work Order Request Process

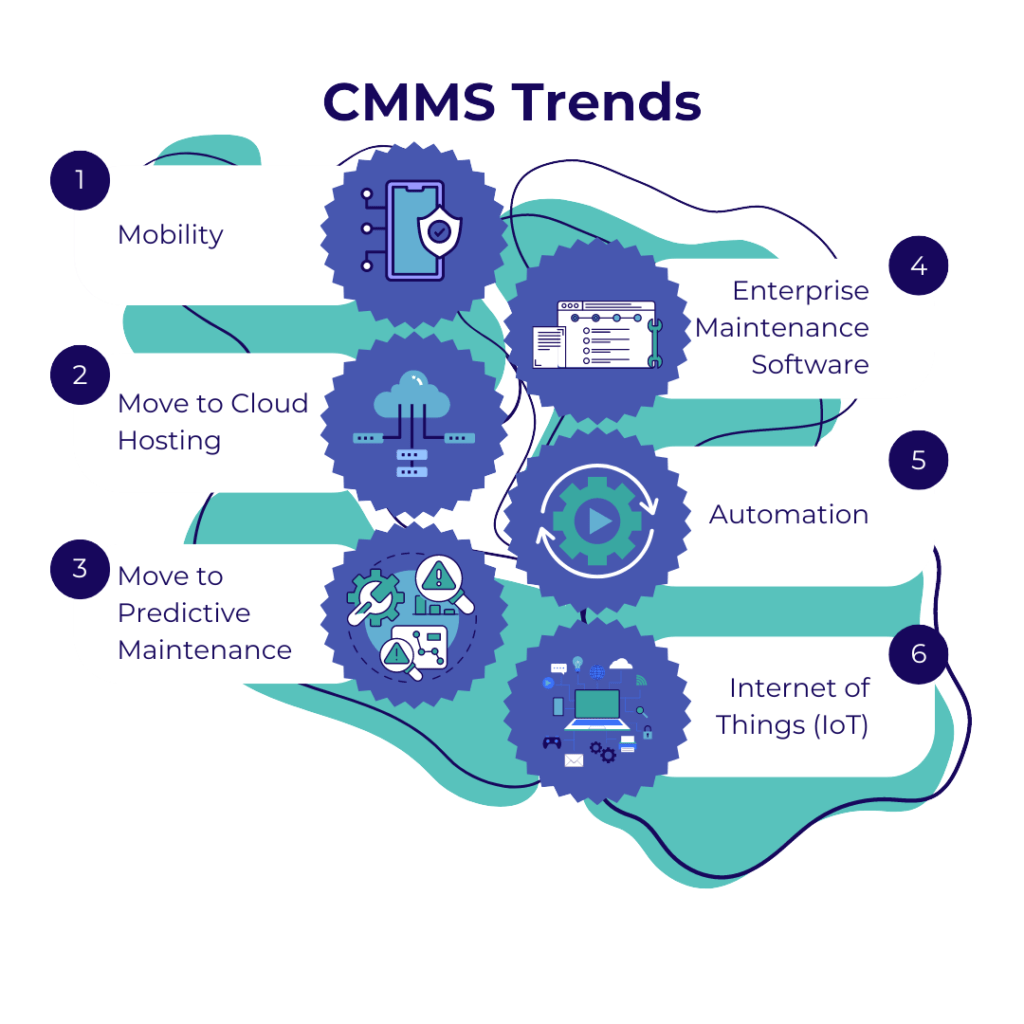

CMMS Software Trends

- Mobility: Cloud CMMS can be accessed from anywhere with an internet connection allowing you to take your system to the job site.

- Move to cloud hosting: Cloud hosting simplifies implementation of your CMMS. Your system is stored on our cloud server so there is no need for hardware or IT assistance.

- Move to Predictive Maintenance: Data collected from your CMMS along with condition monitoring equipment can be used to perform Predictive Maintenance (PdM) on your equipment.

- Enterprise CMMS: Enterprise systems allow large companies to bring multiple locations or departments onto one system. Get all available features and share information across locations.

- Automation: Increased production demands have lead to a rise in automation making preventive maintenance more challenging and more important than ever.

- Internet of Things (IoT): Equipment can now be fitted with sensors and software with the purpose of sharing data with other devices via the internet.

CMMS Software Reports and Data

COGZ CMMS Software reports tracks preventive, scheduled and breakdown maintenance activities. View historical reports to prove compliance or to plan for the upcoming year.

CMMS Reports provide the documentation needed for management and auditors. Get the data you need to analyze and optimize your maintenance operation.

CMMS Software Frequently Asked Questions

What is the best CMMS Software?

COGZ is flexible enough to be used in any maintenance operation. It offers the opportunity for customization, mobility and scalability. It is simple to use and makes maintenance management easier.

What is the price of CMMS Software?

Pricing depends on the features and number of users your maintenance department requires. See our Pricing page determine what COGZ version best meets your needs.

Who uses CMMS Software?

CMMS Software is used in maintenance departments throughout a variety of industries. Manufacturing, Industrial, Food Processing, Healthcare, Education, Retail, Energy, Government and Hospitality are just some of the industries experiencing the benefits of Maintenance Software. Maintenance technicians, Maintenance Managers, Facility Managers, Engineers and executives are just some of the individuals who use CMMS to manage their operations every day.

Is training available?

COGZ offers live online training in 90 minute sessions. Sessions are fully customizable based on your specific needs. Contact us if you wish to schedule an online training session

Can I connect CMMS Software to SAP?

COGZ CMMS has the ability to interface with SAP as well as other Accounting or ERP software. All of our interfaces are customized to your exact specifications.

Is my CMMS data secure?

Cloud CMMS Software is the most secure CMMS solution. Data is stored on cloud servers which are specifically designed by security experts to be as safe as possible. Backups are performed frequently and are stored offline and offsite.

What is the difference between CMMS Software and EAM?

CMMS is a Computerized Maintenance Management System. It is an all-in-one maintenance solution that schedules preventive maintenance and other work orders. EAM is Enterprise Asset Management software. EAM manages assets throughout their entire lifecycle including depreciation and heavy financial metrics. These systems are substantially more costly and more challenging to use.